ERDI

Contact Us

Senior Engineer, Yilin

- Tel : +86 28 81076698

- WhatsApp : +86 18000520222

Customer Reviews

Our team has been using ERDI products. They provide excellent services and can quickly solve the technical problems of the products. In particular, the perfection of their entire industrial chain in the field of distance measurement has greatly facilitated our secondary development

We are very grateful to the technical engineers of ERDI for their on-site technical guidance at our company. Their visit has accelerated the research and development of our unmanned aerial vehicle (UAV) system. The products of ERDI have demonstrated remarkably stable performance.

We're extremely thankful to ERDI's engineers for coming to our office for detailed product training. Their expertise in communication modules has been a huge boon for our telecom project. The ERDI communication products we've incorporated into our system have shown outstanding stability, significantly enhancing the efficiency of our R & D work.

FAQ

We are a national high-tech enterprise in China. For each product, we cover the entire industrial chain, ranging from research and development to manufacturing, and then to technical service solutions.

We provide samples and will try our best to keep the fees as low as possible. If you are our regular customer, we will offer some free samples.

You can contact sales online to get latest price; Or you can leave message to us. Our sales will contact you as soon as possible. And the price we provide is normally FOB price.

We accept payments via T/T, PayPal and LC.

Our minimum order quantity is 1 pc.

Please contact sales to confirm if we still have goods in stock. If yes, we will ship goods to you in one week time after we receive your payment. If not, please confirm with sales.

Usually we ship goods to customer via express, such as DHL, FedEx, UPS, TNT or airway transportation. You can also ask us to send goods to your forwarder in China. And we will pay domestic freight.

Yes, we provide OEM/ODM service. Lead time of customized products need to be confirmed with sales. Usually we will ship products after 2 months time after we receive customer’s payment.

Our skilled and friendly salesmen are ready to answer your questions about our products and services at any time, from product selection to application. Free technical consultation services are offered by request. Our experienced engineers are here to cooperate with you on your special requirements or OEM designs.

The specifications of our products are subject to change without notice. Please ask necessary questions before you order.

Laser products are warranted to conform to ERDI’ s published specifications and to be free from defects in materials and workman-ship for a period of twelve months starting on the shipping date. ERDI will repair or replace (at our decision) ASAP without charge, any part(s) found to be defective during the warranty period.

Our warranties do not cover damages due to misuse, negligence or accidents or due to installations, repairs or adjustments not authorized by ERD.

If a problem occurs and can’t be solved by phone, fax, or email, you may return products to ERDI. Please contact us for a Return Material Authorization (RMA) number prior to shipping the laser. We’ll provide you details on shipping and customs information with the RMA number. All lasers and components should be carefully packed to avoid damage during shipment.

Diode Lasers vs. DPSS Lasers: What’s the Difference?

- ERDI

- No Comments

Lasers have become an integral part of modern technology, powering everything from medical devices to industrial equipment. Among the most commonly used types are Diode Lasers and DPSS (Diode-Pumped Solid-State) Lasers. While both serve crucial roles, their design, functionality, and applications differ significantly. This article will explore these differences, helping readers understand which type of laser best suits their needs.

What Are Diode Lasers?

Diode lasers, also known as semiconductor lasers, are compact and efficient devices that generate light through the direct conversion of electrical energy. Their simple construction involves a p-n junction diode that emits photons when current flows through it. This design allows diode lasers to be small, lightweight, and highly energy-efficient.

What Are Diode Lasers?

One of the greatest strengths of diode lasers is their versatility. They are widely used in everyday applications such as barcode scanning, fiber optic communication, and consumer electronics like Blu-ray players. Their affordability and low maintenance make them a preferred choice for mass-market products and portable devices.

Advantages of Diode Lasers

- Energy Efficiency: Diode lasers convert electrical energy directly into light with minimal losses, making them highly efficient and cost-effective to operate.

- Compact and Lightweight: Their simple construction enables small and portable designs, suitable for consumer electronics and handheld devices.

- Instantaneous Modulation: Diode lasers can be turned on and off almost instantly, with modulation rates far exceeding the typical 20kHz maximum of DPSS lasers. This makes them highly effective for laser shows and data transmission.

- Stability: They are less prone to mode hopping or fluctuations, providing consistent and reliable output under varying conditions.

- Safety: Unlike DPSS lasers, diode lasers do not emit residual infrared radiation, reducing certain safety concerns.

- Lower Manufacturing Costs: The straightforward design of diode lasers leads to lower production and maintenance costs, making them accessible for widespread use.

- Simpler Cooling Requirements: Diode lasers are less temperature-sensitive and typically do not require the precise thermal management needed by DPSS systems.

The Challenges of Diode Lasers

- Beam Quality at High Power: As power increases, the beam quality tends to decrease, often requiring corrective optics to maintain performance.

- Divergence: High-power diode lasers exhibit significant beam divergence, which limits precision and necessitates specialized collimation optics.

- Multi-Emitter Design Issues: High-power diode lasers frequently use multiple emitters, making their output difficult to collimate into a uniform beam. This can lead to inconsistencies in applications requiring tight focusing.

- Thermal Management: Although less temperature-sensitive than DPSS lasers, high-power diode lasers still require effective heat dissipation to prevent performance degradation and ensure longevity.

- Limited Beam Quality at Long Distances: At extended ranges, diode lasers often struggle to maintain a consistent, focused beam, especially when compared to DPSS lasers.

- Beam Quality at High Power: As power increases, the beam quality tends to decrease, often requiring corrective optics to maintain performance.

- Divergence: Significant beam divergence can limit precision and require specialized collimation

What Are DPSS Lasers?

Diode-pumped solid-state lasers, commonly known as DPSS lasers, have a more complex setup. They begin with a laser diode that emits light at an initial wavelength. This light is then passed through one or more crystals, referred to as gain media, to modify the wavelength.

For example, the popular green 532nm DPSS lasers start with an 808nm diode. That light is pumped through a crystal, converting it to 1064nm. It then passes through another crystal that halves the wavelength, creating the final green beam at 532nm.

What Are DPSS Lasers?

Why Use DPSS Lasers?

If they’re less efficient and more finicky, why bother with DPSS lasers? It all comes down to wavelength availability. Laser diodes only exist for certain wavelengths within the visible spectrum (400nm to 700nm). Some wavelengths, like yellow, are incredibly difficult and expensive to produce with diodes alone. DPSS technology fills this gap, allowing us to create colors like green, yellow, and blue even when diode equivalents don’t exist.

Advantages of DPSS Laser

- Superior Beam Quality: DPSS lasers generate beams with low divergence and small diameters, ensuring high precision and clarity even at higher power levels.

- Wavelength Versatility: Through frequency doubling and other techniques, DPSS lasers can produce unique wavelengths, such as green and ultraviolet, which are difficult to achieve with diode lasers.

- High Output Power with Precision: They can deliver high power while maintaining exceptional beam quality, making them ideal for demanding industrial and medical applications.

- Precision in Applications: The highly focused beams are perfect for detailed tasks like engraving, spectroscopy, and laser surgery.

- Temperature-Optimized Performance: When maintained within precise temperature ranges, DPSS lasers offer consistent and optimal performance over time.

- Specialized for Demanding Tasks: Applications requiring unique wavelengths or extremely focused beams benefit greatly from DPSS laser technology.

The Challenges of DPSS Lasers

- Temperature Sensitivity: They work best within a narrow temperature range, making them less versatile outdoors or in fluctuating environments.

- Low Efficiency: Many DPSS lasers convert under 5% of the diode’s energy into the output beam. For context, an 808nm diode producing 1 watt of power may yield only 20 milliwatts of usable light in rare cases, like blue (473nm) or yellow (589nm) DPSS lasers.

- Larger Size: The internal components needed for wavelength conversion require more space, often resulting in bulkier designs.

Diode Lasers vs. DPSS Lasers

| Feature | Diode Lasers | DPSS Lasers |

| Beam Quality | Lower at high power; requires correction optics | Superior with low divergence and small beams |

| Wavelength Range | Limited; infrared and some visible light | Wide; includes green and ultraviolet |

| Efficiency | Highly efficient | Lower efficiency (e.g., 25% for 532nm) |

| Power Scalability | Moderate | High with excellent precision |

| Cost | Affordable and easy to produce | Expensive due to the complex design |

| Temperature Sensitivity | Less dependent on temperature | Highly sensitive; requires precise cooling |

| Modulation Capability | Instantaneous, fast rates | Limited to ~20kHz |

| Applications | Consumer electronics, data transmission | Medical, industrial, and scientific applications |

Why Both Lasers Matter

Each type has its place in the laser world. Direct diode lasers excel in simplicity, efficiency, and versatility, making them perfect for widely available colors like red and blue. DPSS lasers, despite their inefficiency and higher cost, offer solutions for wavelengths that diode technology can’t yet achieve.

When selecting a laser, think about your needs. If you want something compact and durable, a direct diode model might be the way to go. But if you’re after unique or hard-to-find colors, a DPSS laser is your best bet.

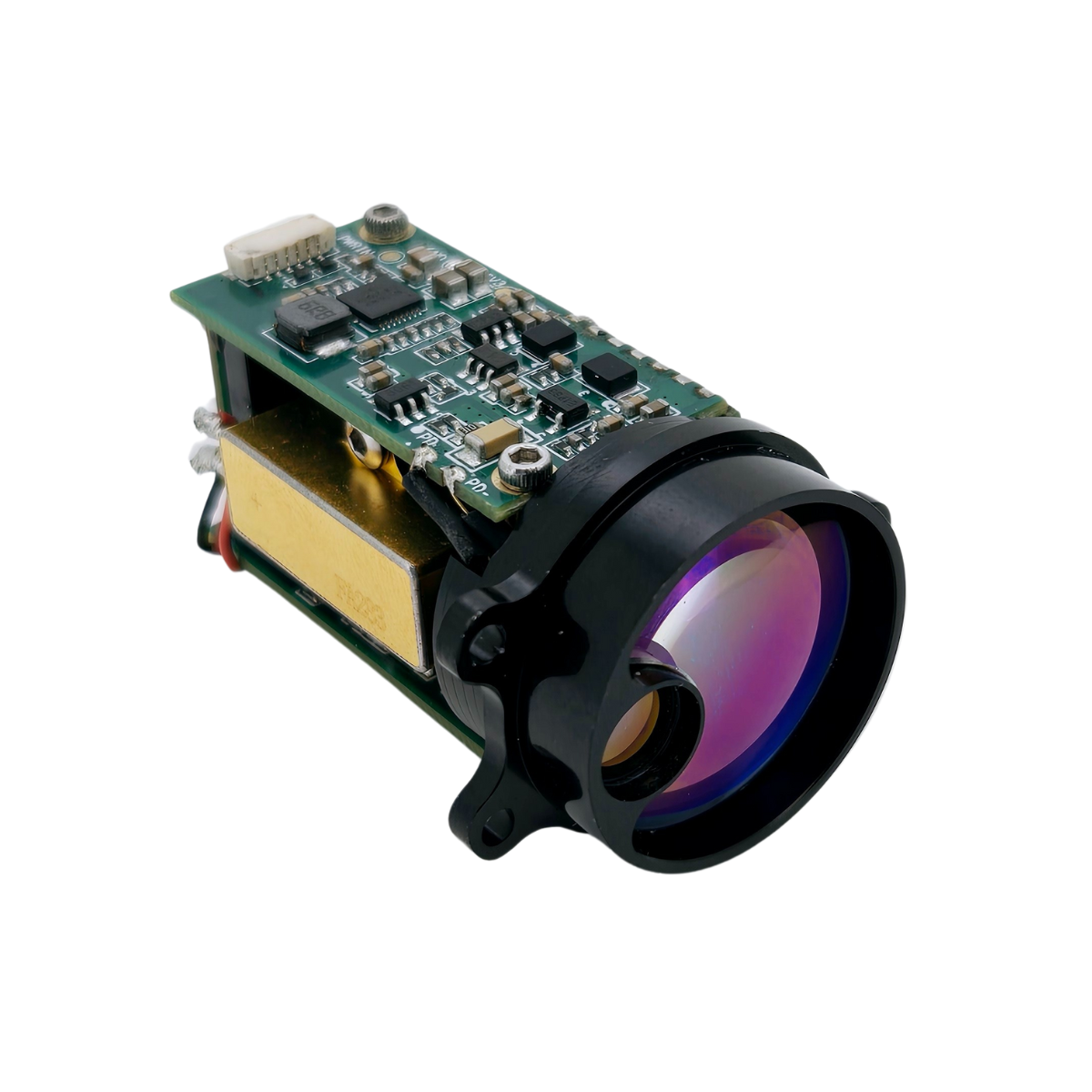

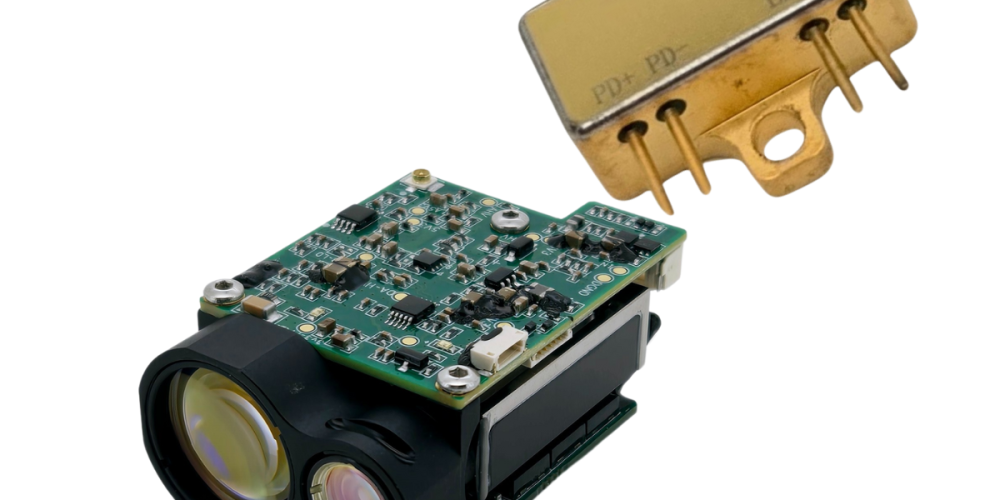

Looking for a cutting-edge laser solution? Consider our Microchip Laser Module 200μJ. This 1535 nm Er:Yb: glass laser is engineered for unmatched precision and safety. Its wavelength falls perfectly within the eye-safe and atmospheric windows, making it ideal for a range of applications:

- Laser Ranging: Achieve distances of 3-8 km with pulse energy of ≥200 μJ.

- Laser Target Designation: Pinpoint accuracy for military or industrial tasks.

- Laser Illumination: Reliable performance for various lighting needs.

- Lidar Systems: Advanced technology for environmental mapping and navigation.

- Medical Applications: Safe and effective in laser treatments.

- Fiber Optic Communications: Cutting-edge capabilities for signal transmission.

Whether you’re buying a single module or outfitting a full system, we offer flexible purchasing options to meet your needs. Plus, the more you buy, the greater the discounts! Don’t miss out—invest in the reliability and performance of our Microchip Laser Module 200μJ today. Contact us to learn more or place your order now!

Conclusion

Diode lasers and DPSS lasers each have their unique strengths and weaknesses, making them suitable for different purposes. Diode lasers excel in efficiency, cost, and modulation speed, making them perfect for consumer and communication applications. In contrast, DPSS lasers shine in high-power, precision-demanding tasks, offering superior beam quality and access to specialized wavelengths. Selecting the right laser depends on the specific requirements of the application, including budget, performance needs, and operating environment.