ERDI

Contact Us

Senior Engineer, Yilin

- Tel : +86 28 81076698

- WhatsApp : +86 18000520222

Customer Reviews

Our team has been using ERDI products. They provide excellent services and can quickly solve the technical problems of the products. In particular, the perfection of their entire industrial chain in the field of distance measurement has greatly facilitated our secondary development

We are very grateful to the technical engineers of ERDI for their on-site technical guidance at our company. Their visit has accelerated the research and development of our unmanned aerial vehicle (UAV) system. The products of ERDI have demonstrated remarkably stable performance.

We're extremely thankful to ERDI's engineers for coming to our office for detailed product training. Their expertise in communication modules has been a huge boon for our telecom project. The ERDI communication products we've incorporated into our system have shown outstanding stability, significantly enhancing the efficiency of our R & D work.

FAQ

We are a national high-tech enterprise in China. For each product, we cover the entire industrial chain, ranging from research and development to manufacturing, and then to technical service solutions.

We provide samples and will try our best to keep the fees as low as possible. If you are our regular customer, we will offer some free samples.

You can contact sales online to get latest price; Or you can leave message to us. Our sales will contact you as soon as possible. And the price we provide is normally FOB price.

We accept payments via T/T, PayPal and LC.

Our minimum order quantity is 1 pc.

Please contact sales to confirm if we still have goods in stock. If yes, we will ship goods to you in one week time after we receive your payment. If not, please confirm with sales.

Usually we ship goods to customer via express, such as DHL, FedEx, UPS, TNT or airway transportation. You can also ask us to send goods to your forwarder in China. And we will pay domestic freight.

Yes, we provide OEM/ODM service. Lead time of customized products need to be confirmed with sales. Usually we will ship products after 2 months time after we receive customer’s payment.

Our skilled and friendly salesmen are ready to answer your questions about our products and services at any time, from product selection to application. Free technical consultation services are offered by request. Our experienced engineers are here to cooperate with you on your special requirements or OEM designs.

The specifications of our products are subject to change without notice. Please ask necessary questions before you order.

Laser products are warranted to conform to ERDI’ s published specifications and to be free from defects in materials and workman-ship for a period of twelve months starting on the shipping date. ERDI will repair or replace (at our decision) ASAP without charge, any part(s) found to be defective during the warranty period.

Our warranties do not cover damages due to misuse, negligence or accidents or due to installations, repairs or adjustments not authorized by ERD.

If a problem occurs and can’t be solved by phone, fax, or email, you may return products to ERDI. Please contact us for a Return Material Authorization (RMA) number prior to shipping the laser. We’ll provide you details on shipping and customs information with the RMA number. All lasers and components should be carefully packed to avoid damage during shipment.

Working Principle and Typical Applications of Fast Steering Mirror (FSM)

- Yilin

- No Comments

I. Working Principle of Fast Steering Mirror (FSM)

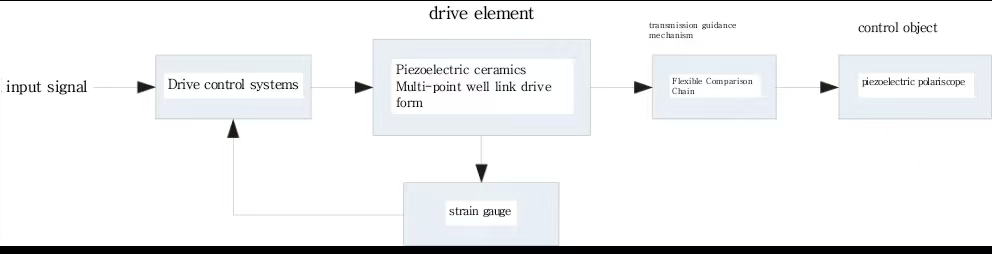

- Drive Unit: Piezoelectric ceramics (achieving nanometer-level displacement using the inverse piezoelectric effect).

- Transmission Mechanism: Flexible hinges (no mechanical friction, transmitting motion through elastic deformation).

- Feedback Unit: Strain gauges or capacitive sensors (full closed-loop control accuracy reaching the μrad level).

- Reflective Mirror: Made of fused quartz or silicon carbide (surface profile accuracy ≤ λ/4 RMS).

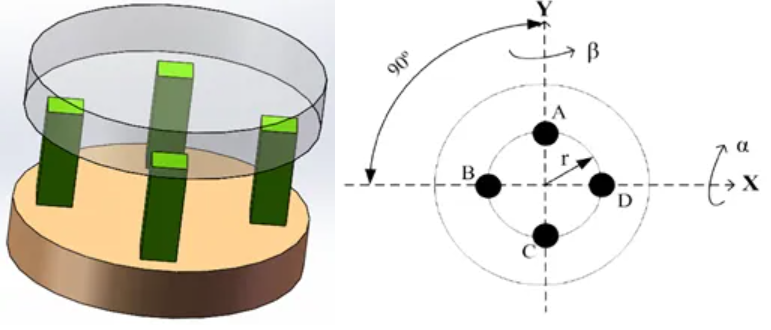

Taking a four-point driven fast steering mirror as an example, the schematic diagram of the two-dimensional worktable is as follows. A, B, C, and D are all piezoelectric ceramic actuators, and the four driving elements of this fast tilting mirror are evenly distributed at 90° in the XY plane.

The tilting mirror operates by using the inverse piezoelectric effect of piezoelectric ceramics to drive the tilting mirror plate. During operation, a voltage is applied to the piezoelectric ceramics through a controller, causing them to extend or contract. When the extension amount is approximately half of their maximum displacement, the mirror position of the deflection platform at this moment is taken as the reference plane. The control voltages at both ends of piezoelectric ceramics A and C remain unchanged, while the control voltages of the two piezoelectric ceramics B and D installed along the X-axis are adjusted, causing one of the piezoelectric ceramics to extend and the other to contract. The movement of the two piezoelectric ceramics is transmitted through the elastic deformation of the flexible ring, thereby achieving the deflection movement of the deflection platform around the Y-axis. By the same principle, the deflection of the tilting mirror around the X-axis can be realized.

II. Application Fields of Fast Steering Mirror (FSM)

1. Laser Communication (ATP Technology)

- Bandwidth Advantage: The information capacity is several times higher than that of microwave communication.

- Power Consumption Optimization: The terminal power consumption is ≤30 W (average value), suitable for satellite platforms.

- Anti-Interference Capability: With a μrad-level image stabilization accuracy, it suppresses atmospheric turbulence and carrier jitter.

2. Image Stabilization System Applications

- Dynamic Image Stabilization: In airborne/vehicle-borne optoelectronic systems, high-frequency deflection compensates for platform vibrations, achieving an image stabilization accuracy with a 5 ms step response.

- Optical Path Calibration: Corrects beam tilt errors in laser processing equipment to improve processing consistency.

3. Astronomical Observation

- Telescope Pointing Stabilization: Real-time correction of low-frequency aberrations caused by atmospheric disturbances to enhance observation resolution.

III. Typical Manufacturers: Technical Routes and Product Comparisons

1. Internationally Leading Enterprises

- Physik Instrumente (Germany): A representative manufacturer of piezoelectric fast steering mirrors (FSMs), renowned for products with nanometer-level resolution and kilohertz-level bandwidth, such as the S-340 series.

- Raytheon (USA): A technology leader in voice coil motor-driven FSMs, whose Responder series offers a deflection angle of ±10 mrad, suitable for space laser communication.

2. Core Chinese Manufacturers

- Sanying Precision Control: Specializing in piezoelectric drive technology, its NS-RB series FSMs achieve a closed-loop resolution of 0.1 μrad, adapted for lidar and satellite communication scenarios.

- Dianhui Technology: Develops voice coil motor-driven products (e.g., FSM-720 series) supporting ±1.5° mechanical deflection, applied in optical image stabilization and laser processing. If you encounter confusion in FSM selection, feel free to jump to read Dianhui Technology’s series of articles to easily master the key points of model selection.

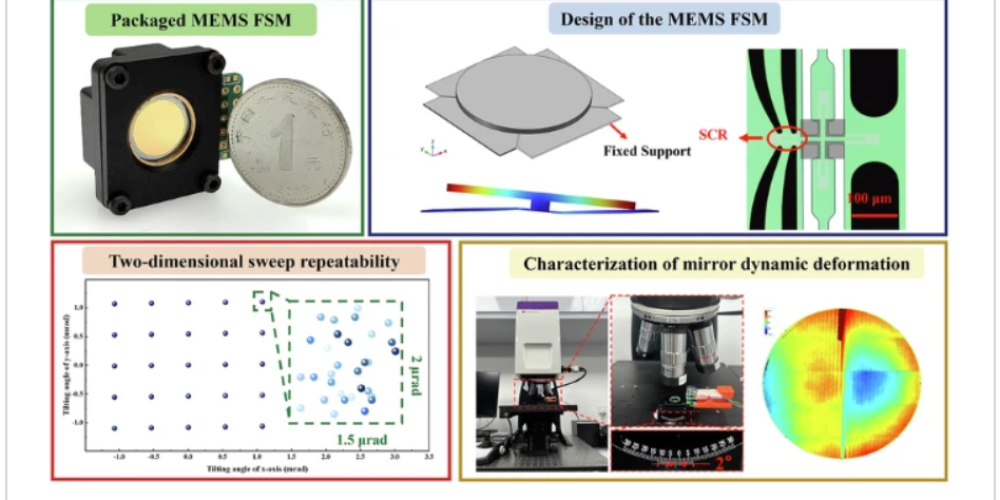

- Shanghai Institute of Microsystem and Information Technology, Chinese Academy of Sciences: Successfully developed a 10-mm large-aperture piezoelectric MEMS (Micro-Electro-Mechanical System) fast steering mirror.