ERDI

Contact Us

Senior Engineer, Yilin

- Tel : +86 28 81076698

- WhatsApp : +86 18000520222

Customer Reviews

Our team has been using ERDI products. They provide excellent services and can quickly solve the technical problems of the products. In particular, the perfection of their entire industrial chain in the field of distance measurement has greatly facilitated our secondary development

We are very grateful to the technical engineers of ERDI for their on-site technical guidance at our company. Their visit has accelerated the research and development of our unmanned aerial vehicle (UAV) system. The products of ERDI have demonstrated remarkably stable performance.

We're extremely thankful to ERDI's engineers for coming to our office for detailed product training. Their expertise in communication modules has been a huge boon for our telecom project. The ERDI communication products we've incorporated into our system have shown outstanding stability, significantly enhancing the efficiency of our R & D work.

FAQ

We are a national high-tech enterprise in China. For each product, we cover the entire industrial chain, ranging from research and development to manufacturing, and then to technical service solutions.

We provide samples and will try our best to keep the fees as low as possible. If you are our regular customer, we will offer some free samples.

You can contact sales online to get latest price; Or you can leave message to us. Our sales will contact you as soon as possible. And the price we provide is normally FOB price.

We accept payments via T/T, PayPal and LC.

Our minimum order quantity is 1 pc.

Please contact sales to confirm if we still have goods in stock. If yes, we will ship goods to you in one week time after we receive your payment. If not, please confirm with sales.

Usually we ship goods to customer via express, such as DHL, FedEx, UPS, TNT or airway transportation. You can also ask us to send goods to your forwarder in China. And we will pay domestic freight.

Yes, we provide OEM/ODM service. Lead time of customized products need to be confirmed with sales. Usually we will ship products after 2 months time after we receive customer’s payment.

Our skilled and friendly salesmen are ready to answer your questions about our products and services at any time, from product selection to application. Free technical consultation services are offered by request. Our experienced engineers are here to cooperate with you on your special requirements or OEM designs.

The specifications of our products are subject to change without notice. Please ask necessary questions before you order.

Laser products are warranted to conform to ERDI’ s published specifications and to be free from defects in materials and workman-ship for a period of twelve months starting on the shipping date. ERDI will repair or replace (at our decision) ASAP without charge, any part(s) found to be defective during the warranty period.

Our warranties do not cover damages due to misuse, negligence or accidents or due to installations, repairs or adjustments not authorized by ERD.

If a problem occurs and can’t be solved by phone, fax, or email, you may return products to ERDI. Please contact us for a Return Material Authorization (RMA) number prior to shipping the laser. We’ll provide you details on shipping and customs information with the RMA number. All lasers and components should be carefully packed to avoid damage during shipment.

What is a Laser Diode & How Does it Work

- ERDI

- No Comments

Alaser diode is a type of semiconductor device that generates coherent light through a process known as stimulated emission. It shares many similarities with light-emitting diodes (LEDs), but with one significant difference: it produces laser light, which is far more focused and coherent.

In this article, we’ll delve into the fundamentals behind laser diodes and explore the scientific principles that make them so efficient and indispensable.

What Makes a Laser Special?

To understand how laser diodes function, it’s essential to first grasp what sets lasers apart from conventional light sources. The acronym “LASER” stands for Light Amplification by Stimulated Emission of Radiation, a principle that highlights two critical characteristics:

- Spatial Coherence: Unlike a standard light bulb, which emits light in all directions, a laser produces a highly concentrated beam of light. This spatial coherence allows lasers to achieve remarkable precision, whether it’s for long-range targeting, laser engraving, or optical communication.

- Temporal Coherence: The light emitted by a laser consists of photons that are synchronized in both frequency and phase. This temporal coherence ensures that all photons oscillate in unison, which is key to the laser’s ability to deliver coherent and stable light over long distances.

In contrast, natural light sources like the sun or light bulbs emit photons in random directions, with varying wavelengths and phases. This scattering of light makes lasers uniquely suited for applications requiring high precision and intensity.

A Quick Photon Primer

Before diving deeper, it’s important to understand the fundamental unit of light: the photon. A photon is both a particle and a wave, capable of carrying energy. The energy of a photon determines its wavelength (color) and frequency (the number of oscillations per second).

In a laser, photons are meticulously controlled. Unlike sunlight, where photons are emitted in random directions, laser photons are emitted in a highly organized manner, maintaining consistent direction and energy. This uniformity is key to the laser’s coherence and focus.

How Laser Diodes Actually Work

Laser diodes are a type of laser that produces coherent light through some clever engineering. They use semiconductors, much like the light-emitting diodes (LEDs) you’re probably already familiar with. Here’s how they work step by step:

The Role of Semiconductors

A laser diode consists of two semiconductor materials:

- N-Type Semiconductor: This layer has extra electrons (negative charge).

- P-Type Semiconductor: This layer has “holes” where electrons are missing (positive charge).

When you connect these semiconductors to a power source, electrons move from the N-layer to the P-layer. This process creates an interaction between electrons and holes at their interface, releasing energy in the form of light. But this is still just the beginning.

Spontaneous vs. Stimulated Emission

When an electron in the N-layer recombines with a hole in the P-layer, a photon is released. This is called spontaneous emission, and it happens naturally whenever electrons interact with holes.

However, laser diodes take things up a notch. If a photon passes through these same materials, it can trigger an additional reaction called stimulated emission. Here’s the key: the new photon generated will have the exact same frequency, phase, and polarization as the original one. This is the secret sauce that allows lasers to emit perfectly synchronized light.

Amplifying Light with a Resonator

To maximize stimulated emission, laser diodes include an intermediate semiconductor layer. This layer not only improves efficiency but also acts as a channel for photons. Surrounding this layer, a clever arrangement of reflectors, known as a Fabry-Perot resonator, helps trap the photons and keep them bouncing back and forth between two ends.

One side of the resonator is fully reflective, while the other is partially reflective, allowing a small amount of light to escape as the final laser beam. This back-and-forth process amplifies the number of photons generated and helps ensure the light exiting the diode is coherent and intense.

Achieving Temporal Coherence

Even though photons share the same frequency, they can get out of sync after bouncing around inside the resonator. To fix this, the distance between the reflective ends is carefully adjusted to be a multiple of half the photon’s wavelength. This ensures the photons reinforce each other, creating a standing wave.

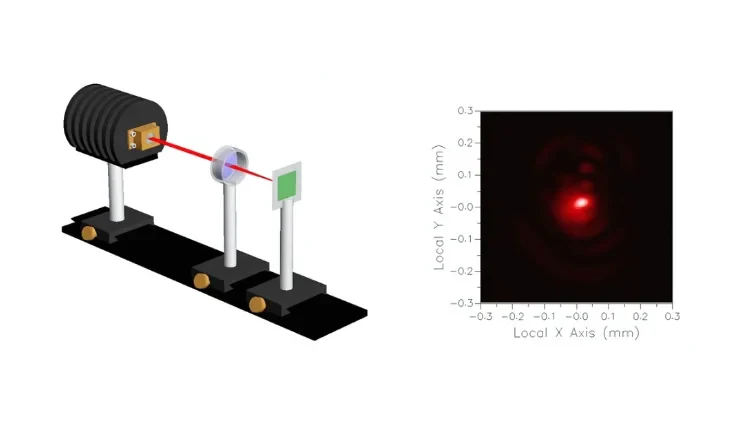

Collimating the Beam

Finally, the laser diode includes a lens to correct spatial dispersion. Without this, photons might scatter slightly, weakening the laser’s focus. The lens straightens the beam, making sure all photons travel in parallel to produce a collimated beam.

Types of Laser Diode

There are several types of laser diodes, each designed to emit a specific wavelength of light, making them suitable for different applications. Here are the most common types of laser diodes, along with their characteristics and typical uses:

Red Laser Diodes

Red laser diodes emit light at a wavelength of approximately 660nm. This wavelength is ideal for applications where visibility and ease of use are important.

Red laser diodes are commonly used in construction and DIY projects, handheld laser pointers, and are also used in applications such as barcode scanning and optical storage devices such as CD players.

Blue Laser Diodes

Blue laser diodes emit light at a shorter wavelength of approximately 450-500nm, typically centered around 488nm. The shorter wavelength makes blue laser diodes particularly useful in applications that require higher energy density and greater precision. Common uses include: welding and material processing, Blu-ray disc players, and their high precision allows for higher data density compared to red laser systems.

Green Laser Diodes

Green laser diodes emit light at a wavelength of 520–550nm, usually around 532nm. Green laser light is particularly visible to the human eye. Some common applications include printers and scanners, tools such as laser rangefinders and levels, and movie projectors.

Green lasers are often used in applications that require high visibility and precision because their wavelength is closer to the peak sensitivity of the human eye, making them appear brighter than red or blue lasers.

Infrared Laser Diodes

Infrared (IR) laser diodes emit light at wavelengths that typically range from 800nm to 1,500nm. Although invisible to the human eye, IR laser diodes are used in a variety of scientific and industrial applications: night vision and lidar, fiber-optic communication systems, and non-invasive medical treatments such as laser surgery.

Types of Laser Diode

Pros and Cons of Laser Diodes

Laser diodes come with some impressive advantages that make them incredibly useful across industries:

- Compact Size: Small enough to fit in consumer electronics.

- Energy Efficiency: Similar to LEDs, laser diodes are economical to operate.

- Durability: They have a long lifespan thanks to semiconductor construction.

- Wavelength Control: Engineers can fine-tune the color and frequency by tweaking the materials used.

That said, laser diodes come with a few drawbacks:

- Heat Generation: Running current through semiconductors generates heat, which requires careful management.

- Beam Quality: Their collimation isn’t as precise as some other types of lasers.

- Limited Power: Compared to other options like gas lasers, diodes are less powerful.

Diode laser Applications

Despite a few limitations, laser diodes have become the go-to solution for countless applications. They’re used in fields like:

- Telecommunications: Fiber optics rely heavily on laser diodes.

- Medical Treatments: From laser eye surgery to dental procedures.

- Manufacturing: Precision cutting and engraving require the focused beams only lasers can provide.

- Autonomous Vehicles: LiDAR systems use lasers to “see” and map their surroundings.

What is the Difference Between LED and Laser Diode?

While both LEDs and laser diodes use semiconductor materials to generate light, the primary difference lies in the way the light is emitted. LEDs emit incoherent light, with photons dispersed randomly in all directions. In contrast, laser diodes produce highly coherent light, with photons emitted in a tightly controlled and synchronized manner.

Read more: Diode Lasers vs. DPSS Lasers

Conclusion

Laser diodes are a perfect example of a small but mighty technology. By combining the principles of semiconductors, photons, and quantum mechanics, they generate precise, coherent light that powers some of the most advanced systems we use today.

Whether scanning barcodes or enabling self-driving cars, laser diodes prove that great things truly do come in small packages.